- Sail Loot Podcast 063: Sailing With FIRE on Luna Sea with Mark and Jennifer

- Sail Loot Podcast 062: Andersons Abroad own Sea-Tech Systems to make Sailing Money

- Sail Loot Podcast 048: Neil Davies Sails to Cuba and Works Remotely for Sailing Money

- Sail Loot Podcast 042: Wiley Sharp, Part 2 – Owning and Operating a Virgin Islands Sailing Charter

- Sail Loot Podcast 037: Salty Times Sailing to find the Surf with Base and Jamie

- Sail Loot Podcast 027: Couchsailors Jose and Gina Rent All of their Rooms for Sailing Money

- Sail Loot Podcast 020: Leah Kruger Makes Her Sailing Money With Brio

- Sail Loot Podcast 019: Good Anchorage, Get Paid To Cruise

- Sail Loot Podcast 013: Investing Money to Make Money While Sailing the Mediterranean with Franz Amussen

- Sail Loot Podcast 012: From Corporate America to Ottsworld with Sherry Ott

Bareboat Cruising Course: The Third Step To Improving Our Sailing Skills – Day 1 (Day 4 Aboard Allison)

Our fourth day aboard Allison started interestingly to say the least. Tom, our extra instructor, had stayed on board with us while Rory stayed ashore in his own bed. Rory’s house was located in Cane Garden Bay.

So, Tom took the dinghy to meet Rory at the dock at 0800 while the rest of us ate some breakfast and enjoyed our morning coffee.

We were going to spend a few hours practicing our docking at the gas dock in Cane Garden Bay. We went over a few things about docking in our classroom (the saloon) before we weighed anchor and motored over to the gas dock.

Rory would be at the helm first to show us how it was done, explaining everything along the way. The rest of us also needed to learn what to do with the fenders and dock lines. When docking a boat, knowing what to do with the fenders, spring lines, and dock lines is just as important as maneuvering the boat to the dock.

Megan was next at the helm. Rory would always stay at the helm coaching the person who was steering the boat. He would also help hold the wheel in place as an extra precaution in case the wheel lock malfunctioned while using the engines to steer.

Allison was set up so that her rudders were located aft of the propellers. The issue with this configuration is the increased risk of fouling the rudders and the steering system if the rudders aren’t locked in a straight and parallel line with the hull when the engines are used to steer the boat. It could be even more of an issue when an engine/propeller is in reverse, pulling water the “wrong” way over the rudders.

Megan did a great job of docking the boat. She also did a great job of departing the dock. It was my turn for docking practice so I started making my way up to the cockpit. Megan had just left the helm to Rory while we switched and a big gust of wind started pushing us too close to the gas dock. Rory pushed the throttles into reverse, and he reversed hard to keep us from blowing onto the dock.

The next thing you know we heard a large POP! We stopped what we were doing for a minute to try to figure out what we had just heard. Rory unlocked the wheel lock and tried to maneuver the boat.

The next thing I heard was, “We don’t have any steerage.” All things considered, Rory was fairly calm, while the rest of us were in shock, alert, “what do we do now?” mode. He told us to get onto the lines and help him out when he got Allison close to the gas dock. We had to tie her up and see what might have happened. He used the engines to steer us to the dock. We got tied up and it was time for some troubleshooting.

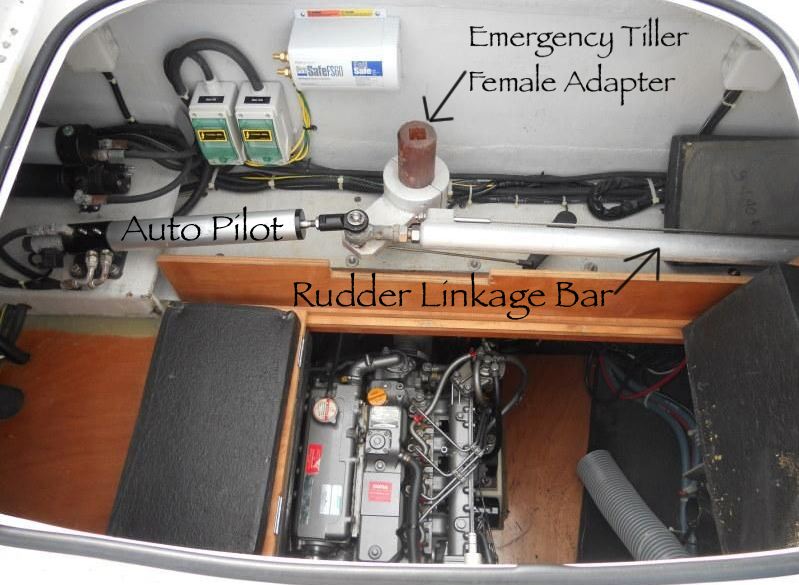

We opened up both engine compartments so that we could see the steering rod and all of the steering linkage. We immediately saw a couple of problems.

Hmm, how to explain this. I think I’m going to have to draw some diagrams and include them. Here we go. Here is a picture of what the port engine compartment on a Lagoon 440 normally looks like.

Steering Linkage Labeled in Port Engine Compartment of Lagoon 440

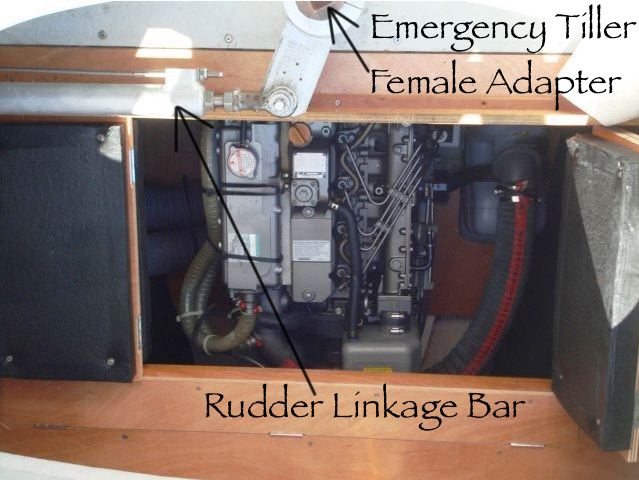

And here is what the starboard engine compartment normally looks like.

Seering Linkage Labeled in Starboard Engine Compartment of Lagoon 440

Actually, the pictures above are showing that the rudders are turned a little to port. They would not be centered and parallel with the hulls.

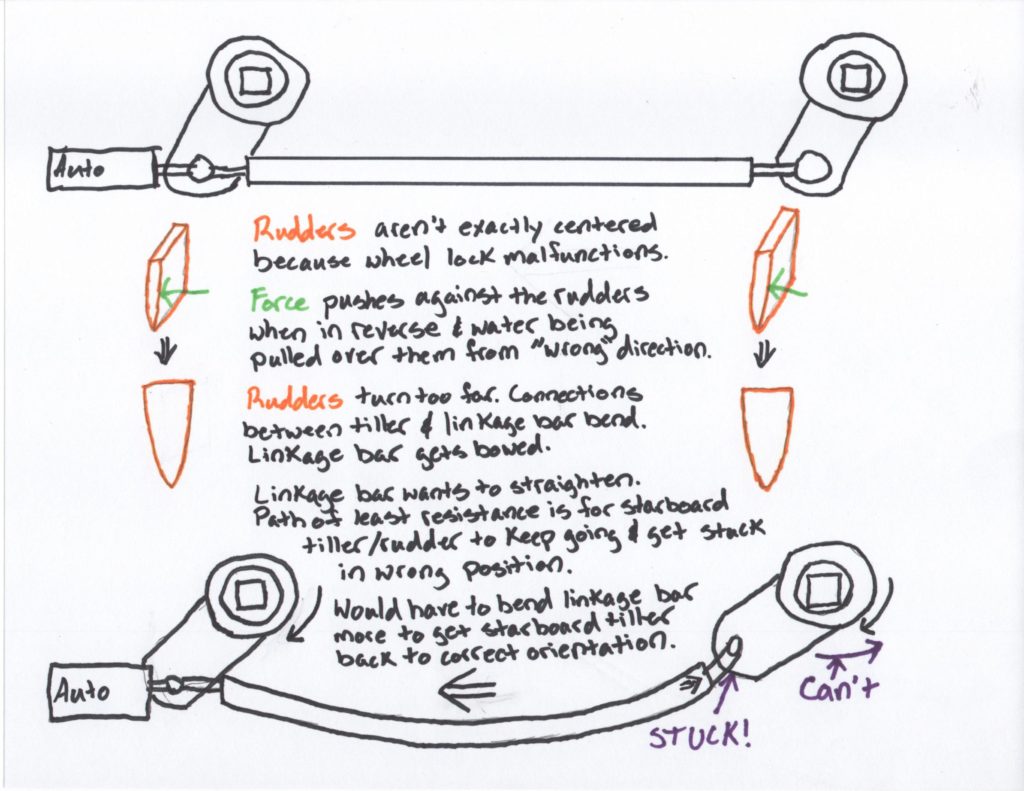

So, the rudder linkage bar got pushed so far to port (or to the left) that the linkage bar bowed. Remember that the boat was pushed hard to reverse and the steering lock malfunctioned. The water pushed on the rudders to the port side of the boat with so much force that the rudder linkage bar was bent and bowed aft.

This also forced the connection point between the rudder linkage bar and the tiller (or what essentially could be the tiller) to snap to the wrong side and get stuck there. Okay, okay, here is one of my terrible drawings.

Allison Failed Steering Diagram

So, we had to get the steering unstuck to proceed. We grabbed the few wrenches, screwdrivers, and what we thought was the emergency tiller that we were given by TMM Yacht Charters. When I brought the emergency tiller out of one of the forward nacelles and back to the starboard engine compartment the first thing that Rory said was, “Where’s the rest of it?”

If you’ve been keeping up with our stories, you may have read about our first Basic Cruising Course Day. In the Pre-Departure Checklists section there’s a note about how Sam pointed out our emergency tiller and said, “Not that you’ll ever need it.” So, when we filled out the checklist, we marked that we had an emergency tiller on board. Apparently, we only had part of it.

Our plan was to use the emergency tiller for some extra leverage on the starboard rudder and try to pop the rudder linkage bar and rudders back into the correct position. This proved to be more difficult without a complete emergency tiller.

We still tried. We found some blocks of wood to get some leverage on the rudder linkage bar. I went up to the helm to use the main steering wheel and when we were all “ready” I turned the wheel to steer towards starboard while Rory and Tom tried to use leverage to get all of the steering components to pop back into the correct position. Nothing we tried worked.

Our only other thought was to take apart the steering linkage. The issue was that we didn’t have enough tools to take on that project by ourselves. One thing we learned was that charter companies don’t really want you to do too much work on their boats. They do supply you with some tools to use in case of emergencies, but if you can’t fix the issue with the tools that they provide, then they would rather you call them so that they can send their own workers to fix the problem.

The good thing was that we were back on Tortola and TMM was located on Tortola. The bad thing was that TMM was located on the other side of Tortola. We called TMM, and we waited.

Even while taking our Bareboat Cruising Course we got a taste of what cruising life can be sometimes. What’s the quote?

“Cruising is working on your boat in exotic locations.”

Yea. That one.

We actually made the best of it and decided to explore the beautiful Cane Garden Bay while we waited. I’m not sure that this is what we “should” have done. We felt a little guilty about leaving Rory and Tom on Allison to wait for TMM Yacht Charters, but they insisted that we go ahead and enjoy the beautiful afternoon.

Fred and Cindy decided to walk along the road to check out a glass blowing hut that Tom had told us about while Megan and I took the dinghy across the bay. I decided that a pain killer was in order while we played in the swimming area for a while. When 3pm rolled around the bar was having happy hour specials and Megan also decided that having a pain killer was the appropriate thing to do.

We explored the bay, walked the beach, and swam around the swimming section until it was almost 4pm. We had all decided that we would be back at Allison by 4pm to get an injury update and figure out future plans. Fred and Cindy had met us down on the beach. We made one quick stop at the provisioning store for some dessert on our way back to the dinghy dock and headed back to Allison.

It was perfect timing! Allison was fixed (mostly)! The guys from TMM Yacht Charters had come out to Allison with all of the correct fittings, bolts, and tools. They popped the rudder linkage bar off of the tillers, put everything back in the correct place, and put everything back together with a few new parts!

With Allison’s steering restored, we could go sailing! We found out that there were some safety stops that had also been broken on Allison’s steering. Those had been removed, and that meant that we would have to be extra careful about holding the wheel when using Allison’s engines to steer while anchoring and docking.

We spent the rest of the day – not that there was much of it left – sailing from Cane Garden Bay on Tortola to Long Bay in between Jost Van Dyke and Little Jost Van Dyke. Luckily, with the sun setting at 7:30pm and all, it was a short sail, but we still took some time to practice our jibes.

We also got a chance to practice anchoring. Actually, we got to practice anchoring twice! Fred and Megan were at the helm and Cindy and I were running the windlass. After the first anchorage, we put the engines in reverse and when we got up to 2500 rpm we all felt like we were slowly dragging the anchor. We would have let out more rode, but Allison’s stern was getting very close to the mooring balls that were behind us.

We pulled the anchor in, and tried again. The second time worked great, and we all got an extra practice round of anchoring! Do you know what a successful anchorage means? Rum drinks!

The blender was broken out once again! Charcoal was lit in the grill on Allison’s stern pulpit. We all chipped in and helped cook chicken and pasta with a nice salad and we spent the evening eating, drinking, watching the tarpon gather at the stern, and sharing sailing stories.

Do you have some sailing stories of your own? Share them with us! Head on over to our Facebook page and say hello!

TeddyJ

One Comment